Flexible Multi-Core Cables

Flexible Multi-Core Cables

Wire & Cables > Multi-Core Cables

What are Multi-Core Cables?

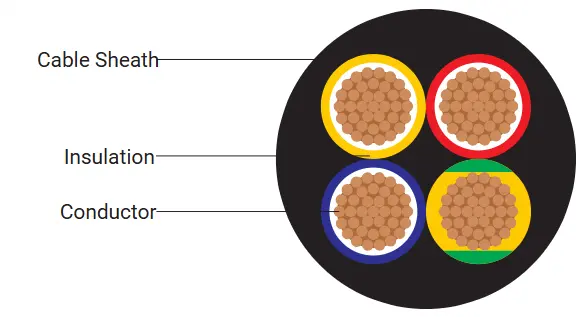

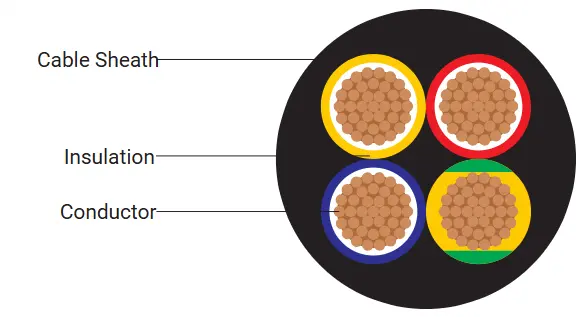

As the name suggests, multi-core cables contain more than one conductor within the insulating coating. Some of these cables have two cores, some have three, and some have five. These cables, though less flexible and with smaller diameters, are more resistant to rapid temperature changes and mechanical stress. Therefore, they are more prone to short circuits, as more work is required when connecting them.

Multi-core cables are used for heavy machinery, such as that found in media studios, engineering centers, and facilities that utilize audio and camera equipment, which are often operated with multi-core cables. In other words, such cables are the best option for industrial applications. The reason is that they are a great source of electrical power and conduction.

4 Core Cable

What are Multi-Core Cables?

These cables are widely used in industrial and heavy-duty applications such as machinery, engineering centers, media studios, and audio-visual equipment, where reliable power transmission is critical.

4 Core Cable

GET YOUR QUOTE NOW

Technical Data

Approvals: IS 694, FIA/TAC

Conductor: Electrolytic annealed copper, Class 5 (IS 8130)

Colours: Black, Grey, White

Voltage Rating: Up to 1100 V

Insulation: FR & FR-LSH

Packing: 100 m coils (custom lengths available)

Size Chart

Cores: 1-8, 10, 12, 14, 16, 19, 20

Sqmm: 0.5, 0.75, 1, 1.5, 2.5, 4, 6, 10, 16, 25, 35, 50, 70, 95, 120, 150, 185, 240, 300

Key Features & Benefits

High flexibility for easy installation in tight spaces

Multi-stranded design for better conductivity and lower losses

Durable insulation resists heat, moisture, and stress

Stable & safe power flow over long periods

Low maintenance with high wear resistance

Reliable performance even with frequent bending